What Innovations Are Paving the Way for Personalized 3D Printed Footwear?

The footwear industry, a significant component of the fashion world, has never been one to lag behind in the adoption of new technologies. In recent years, 3D printing has emerged as a revolutionary tool, enabling shoe manufacturers to create unique, personalized products that not only cater to the latest trends but also address individual needs. The introduction of 3D printing in footwear production has prompted a shift from traditional manufacturing methods, creating a more sustainable, efficient, and waste-reducing process. Today, we explore some of the key innovations that are leading the charge in this sector.

UnionTech’s Pioneering Role in 3D Printing for Footwear

UnionTech is a global leader in the manufacturing and distribution of industrial 3D printers. The company has carved a niche for itself by enabling the adoption of Stereolithography (SLA) technologies within the shoe industry. This technology is known for its high precision, which allows for the creation of intricate designs that were previously challenging or impossible to achieve using traditional methods.

Additional reading : Best practices for organizing and managing your images generated by MyImageGPT

UnionTech’s range of printers, including the RSPro series, are equipped with advanced laser scanning systems and SLA technology, enabling manufacturers to create shoes with unprecedented detail and precision. The use of SLA technology in the footwear industry has proven to be extremely beneficial, not only in terms of design flexibility but also in terms of reducing waste and improving overall sustainability.

Revolutionizing Shoe Design through 3D Printing

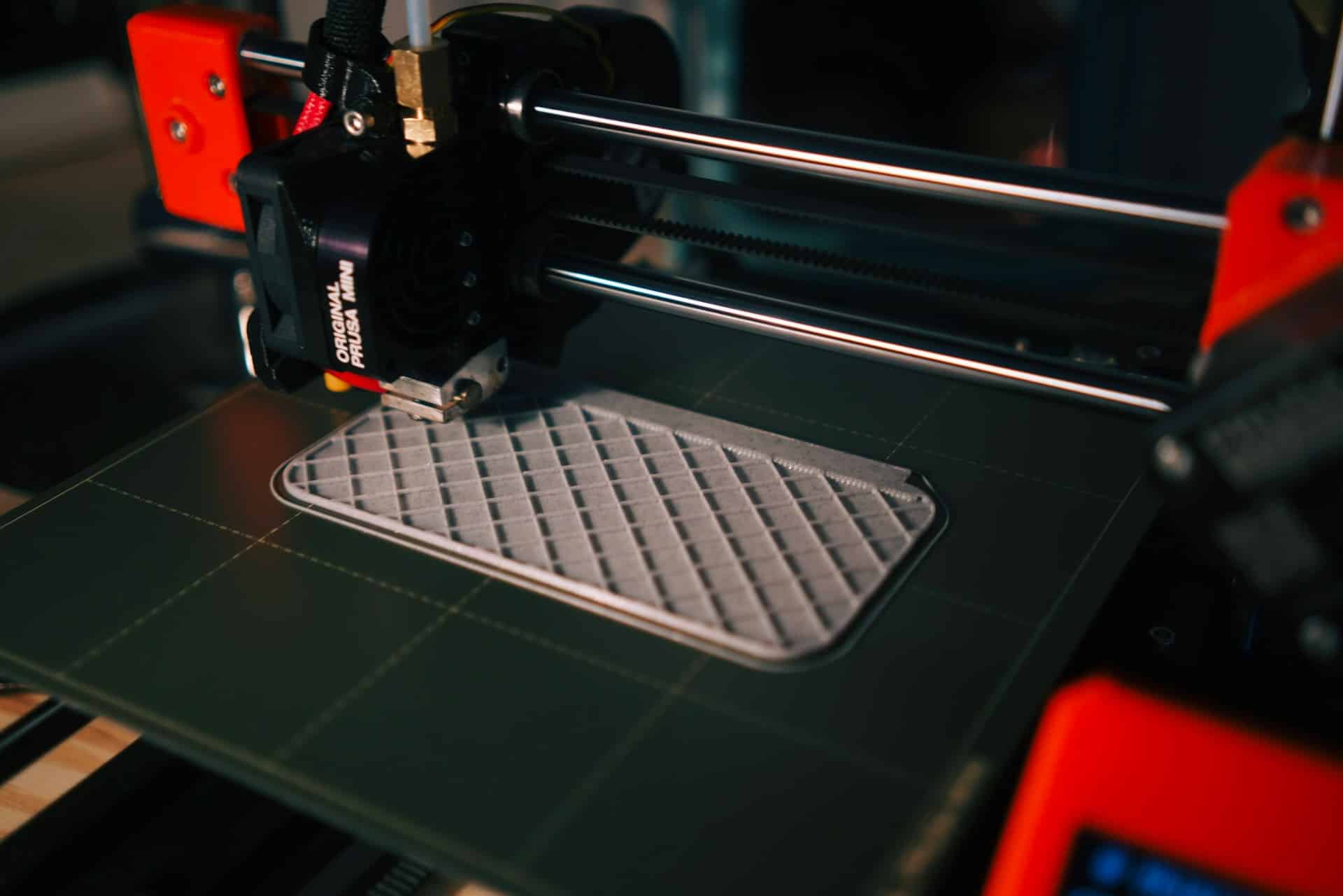

3D printing technology has allowed shoe manufacturers to reimagine the design process. Traditional methods often require physical prototypes, a time-consuming and costly process. However, with 3D printing, designers can create digital models and print them out for testing and evaluation.

In parallel : How Is Blockchain Securing Transparency and Traceability in the Fashion Industry?

Moreover, 3D printing enables the creation of complex geometries and structures that are difficult, if not impossible, to achieve with traditional manufacturing methods. For instance, designers can create shoes with lattice structures, which offer improved flexibility and breathability, without the need for complex and expensive moulds.

The Role of Sustainable Materials in 3D Printed Footwear

3D printing in the footwear industry has not only revolutionized the design and manufacturing process but also played a significant role in promoting the use of sustainable materials. Given the growing concern over environmental impact, many footwear manufacturers are exploring eco-friendly materials for 3D printing.

For instance, options like thermoplastic polyurethane (TPU) and polylactic acid (PLA), both of which are recyclable and biodegradable, are becoming increasingly popular. Not only do these materials provide the flexibility and durability required for footwear, but their use also significantly reduces the industry’s environmental footprint.

3D Printing and Personalized Footwear Production

One of the most exciting developments in the footwear industry is the ability to create personalized shoes using 3D printing technology. Traditionally, shoes have been mass-produced based on standard sizes and shapes. However, 3D printing allows for customization to an individual’s exact foot shape and size.

This level of personalization can significantly improve comfort and performance, particularly in the sports and fitness sector. For instance, athletes can have shoes custom-made to their foot’s unique shape, potentially enhancing performance and reducing the risk of injury.

The Future of 3D Printed Footwear

The continued advancement of 3D printing technology promises an exciting future for the footwear industry. As printers become faster and more efficient, we can expect an increased uptake of this technology across the industry. Furthermore, as sustainable materials become more readily available and affordable, the environmental impact of shoe production is likely to decrease significantly.

Looking ahead, it’s clear that 3D printing will continue to shape the future of the footwear industry, bringing with it a new era of design innovation, sustainability, and personalized products.

Printing Startups Revolutionizing the Footwear Industry

The emergence of printing startups are drastically changing the landscape of the footwear industry. Companies such as UnionTech are disrupting traditional manufacturing processes with their advanced 3D printing technologies. UnionTech printing, in particular, uses industrial SLA and DLP technologies, which are revolutionizing the way footwear is designed and produced.

One of the startups revolutionizing the footwear industry is Adidas Futurecraft. This company uses additive manufacturing to create customized footwear, bringing unprecedented levels of personalization into the market. The use of 3D printing technology enables the creation of shoes that perfectly fit an individual’s foot, promising improved comfort and performance, particularly for athletes.

These startups are not only disrupting traditional manufacturing methods but are also contributing to the sustainability of the footwear industry. By shifting from traditional manufacturing processes to 3D printing, the waste produced during production is significantly reduced. Furthermore, the ability to use sustainable materials such as TPU and PLA in 3D printing further enhances the eco-friendliness of these startups.

Investment Casting and Its Impact on Footwear Mold Production

Investment casting is a manufacturing process that has been widely adopted in the footwear industry, particularly in the creation of shoe molds. Traditionally, shoe molds are created using techniques that are time-consuming and expensive. However, with the advent of 3D printing, the process of creating shoe molds has been significantly simplified.

UnionTech’s SLA printer, with its high precision and advanced laser scanning system, is particularly well-suited for investment casting. The printer can create intricate designs with impeccable precision, making it a versatile tool for the footwear industry.

The process of creating a footwear mold using a 3D printer is simple. A CAD model of the shoe is first created, which is then printed using the SLA printer. The printed model is then used to create a mold, which is used in the production of the shoe. This streamlined process not only reduces waste but also speeds up the production of footwear, making it an efficient alternative to traditional methods.

Conclusion: The Future of the Footwear Industry and 3D Printing

As we look towards the future of the footwear industry, it’s clear that 3D printing is poised to play an increasingly significant role. The advancements in printing technology, spearheaded by startups like UnionTech, are disrupting traditional manufacturing processes and revolutionizing the industry.

With the continued advancement of this technology, we can expect an even more significant shift towards personalized footwear. The apparel industry will likely follow suit, with more brands offering customized products to their customers.

Furthermore, the adoption of 3D printing in the footwear industry has significant implications for sustainability. With startups leading the charge in the use of recyclable and biodegradable materials, the environmental footprint of the industry is likely to decrease significantly.

Overall, the introduction and rapid advancement of 3D printing in the footwear industry is heralding a new era of innovation, sustainability, and personalization. It is an exciting time to witness the transformative power of technology and its potential to reshape industries.